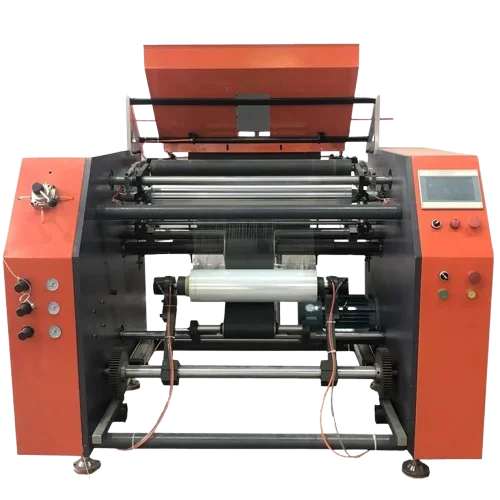

Stretch & Cling Film Rewinder with 500mm Width, 1000m/min Speed & Eco-Friendly Tear Line Cutting

- SKU: CLING FILM RIW INDER

Actual Stock & Price Can Be Confirmed After Placing the Order.

The Stretch and Cling Film Rewinder is designed for rewinding stretch and cling films into smaller sub-rolls with precision and speed. Featuring an eco-conscious design, it enables rewinding while generating a tear line, eliminating the need for toothed knives or blades. With a rewinding... See More

The Stretch and Cling Film Rewinder is designed for rewinding stretch and cling films into smaller sub-rolls with precision and speed. Featuring an eco-conscious design, it enables rewinding while generating a tear line, eliminating the need for toothed knives or blades. With a rewinding width up to 500mm, it supports large mother rolls and efficiently converts them into neatly cut finish rolls. The system offers a max speed of 1000m/min, delivering high productivity while maintaining roll integrity. Its adjustable core compatibility (2-inch, 3-inch) allows flexible output across packaging applications. The rewinder's user-friendly control panel, ergonomic film loading, and low-maintenance operation make it ideal for food-grade packaging, retail wrap, and industrial film use. With smooth cutting, compact form, and reliable output, it reduces material waste and packaging costs.

Key Features

-

Supports 300–500mm Roll Widths – Handles both standard and wide-format mother rolls.

-

Eco-Friendly Tear Line Cutting – Rewinds while creating easy-tear lines, no blades required.

-

Up to 1000m/min Speed – Ensures high-volume film conversion with accuracy.

-

2" & 3" Core Compatibility – Accommodates industry-standard roll cores for output.

-

Max Finish Roll Diameter: 150mm – Delivers compact rolls for direct packing or resale.

-

Precision Control Panel – Allows easy speed regulation and tear-line adjustment.

-

Quick Film Loading System – Designed for minimal downtime and operator safety.

-

Ideal for Food & Packaging Industry – Perfect for kitchen wrap, cling film, and pallet stretch film.

-

No Knife Required – Breaks conventional cutting methods with tear-line innovation.

-

Durable Construction – Engineered for continuous industrial performance.

-

Cost-Efficient Operation – Saves on blade wear, labor, and packaging waste.

-

Compact Floor Design – Fits into production lines or standalone operations easily.

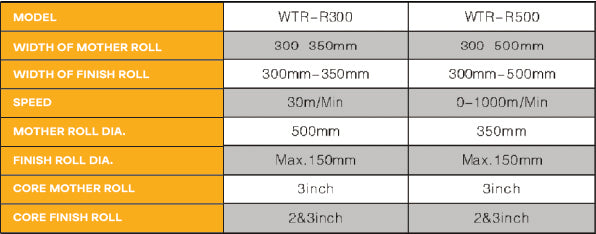

Product Models

| Model | Width of Mother Roll | Width of Finish Roll | Speed | Mother Roll Dia. | Finish Roll Dia. | Core of Mother Roll | Core of Finish Roll |

|---|---|---|---|---|---|---|---|

| WTR–R300 | 300–350mm | 300mm–350mm | 30m/min | 500mm | Max. 150mm | 3 inch | 2&3 inch |

| WTR–R500 | 300–500mm | 300mm–500mm | 0–1000m/min | 350mm | Max. 150mm | 3 inch | 2&3 inch |

The Film Rewinder combines blade-free cutting, eco-friendly rewinding, and speeds up to 1000m/min. Ideal for cling and stretch film production, it offers cost-saving conversion for food, packaging, and retail industries.

| Name | Stretch & Cling Film Rewinder with 500mm Width, 1000m/min Speed & Eco-Friendly Tear Line Cutting |

| Model | CLING FILM RIW INDER |