Plastic Dehumidifier with PID Control, 600KG Hopper Capacity & Siemens Components

- SKU: PLASTIC DEHUMIDIFIER

Actual Stock & Price Can Be Confirmed After Placing the Order.

The Plastic Dehumidifier features a rotor-type design for efficient moisture removal from plastic pellets before processing. It incorporates PID temperature control, displaying return and regenerate air temperatures for accurate system response. With Siemens/OMRON components, quick-coupling TEFLON hoses, and an LCD controller, this system provides... See More

The Plastic Dehumidifier features a rotor-type design for efficient moisture removal from plastic pellets before processing. It incorporates PID temperature control, displaying return and regenerate air temperatures for accurate system response. With Siemens/OMRON components, quick-coupling TEFLON hoses, and an LCD controller, this system provides stable, uninterrupted operation. A 3-minute start delay, overload and phase protection, and an over-temperature alarm ensure safe usage. The system supports up to 600KG hopper insulation and 400–500 m³/h airflow, suitable for medium to high-output extrusion and injection lines. Designed for lightweight mobility, the unit is easy to maintain, highly reliable, and compact for any manufacturing space.

Key Features

-

Rotor Type Drying System – Consistent low dew-point drying and energy efficiency

-

PID Temperature Display – Shows real-time return and regenerate air temperatures

-

Phase, Overload, & Overheat Protection – Safety-first design for continuous operation

-

Delay Start with Fault Shutoff – Prevents premature restarts and equipment damage

-

Up to 600KG Insulated Hopper Tank – Supports large-capacity drying requirements

-

High Air Volume Range – From 60 to 500 m³/h for diverse line demands

-

Siemens and Omron Controllers – Reliable automation with error indication

-

Quick-Coupling TEFLON Hoses – Prevent leaks and contamination

-

Separate Drying and Regeneration Blowers – Efficient dual-blower system

-

Independent Heating Zones – Optimized energy use across stages

-

Low Noise, Lightweight Frame – Compact footprint with caster wheels

-

Ideal for Injection, Extrusion, and Blow Molding – Especially for hygroscopic resins

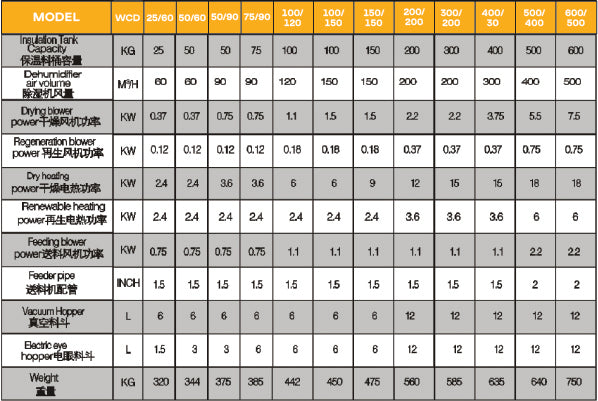

Product Models

| Model | Insulation Tank Capacity (kg) | Dehumidifier Air Volume (m³/h) | Drying Blower Power (kW) | Regeneration Blower Power (kW) | Dry Heating Power (kW) | Renewable Heating Power (kW) | Feeding Blower Power (kW) | Feeder Pipe (inch) | Vacuum Hopper (L) | Electric Eye Hopper (L) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WCD 25/60 | 25 | 60 | 0.37 | 0.12 | 3 | 2.4 | 0.75 | 1.5 | 6 | 1.5 | 320 |

| WCD 50/60 | 50 | 60 | 0.37 | 0.12 | 3 | 2.4 | 0.75 | 1.5 | 6 | 3 | 344 |

| WCD 50/90 | 50 | 90 | 0.75 | 0.12 | 6 | 2.4 | 0.75 | 1.5 | 6 | 3 | 375 |

| WCD 75/90 | 75 | 90 | 0.75 | 0.12 | 6 | 2.4 | 0.75 | 1.5 | 6 | 3 | 385 |

| WCD 100/120 | 100 | 120 | 1.1 | 0.18 | 9 | 2.4 | 1.1 | 1.5 | 6 | 6 | 442 |

| WCD 100/150 | 100 | 150 | 1.5 | 0.18 | 9 | 2.4 | 1.1 | 1.5 | 6 | 6 | 450 |

| WCD 150/150 | 150 | 150 | 1.5 | 0.18 | 9 | 2.4 | 1.1 | 1.5 | 6 | 6 | 476 |

| WCD 200/200 | 200 | 200 | 2.2 | 0.37 | 12 | 3.6 | 1.5 | 1.5 | 12 | 12 | 505 |

| WCD 300/200 | 300 | 200 | 2.2 | 0.37 | 15 | 3.6 | 1.5 | 1.5 | 12 | 12 | 560 |

| WCD 400/30 | 400 | 300 | 3.75 | 0.37 | 15 | 6 | 2 | 2 | 12 | 12 | 635 |

| WCD 500/400 | 500 | 400 | 5.5 | 0.75 | 18 | 6 | 2 | 2 | 12 | 12 | 640 |

| WCD 600/500 | 600 | 500 | 7.5 | 0.75 | 18 | 6 | 2 | 2 | 12 | 12 | 750 |

The Plastic Dehumidifier delivers high-efficiency, safe, and intelligent drying with capacities up to 600KG, 500 m³/h airflow, and independent regeneration systems. Ideal for extrusion, molding, and recycling lines, it ensures dry, defect-free production.

| Name | Plastic Dehumidifier with PID Control, 600KG Hopper Capacity & Siemens Components |

| Model | PLASTIC DEHUMIDIFIER |