No Heater Plastic Recycling Line with Hot Face & Water Ring Cutting

- SKU: NO HEATER RECYCLING LINE

Actual Stock & Price Can Be Confirmed After Placing the Order.

The No Heater Recycling Line uses a high-speed friction method instead of electric coils for heating during plastic granulation. This technology ensures eco-friendly plastic recycling without altering the physical properties of the material. It's ideal for HDPE, LDPE, PVC, and EVA compound film waste.... See More

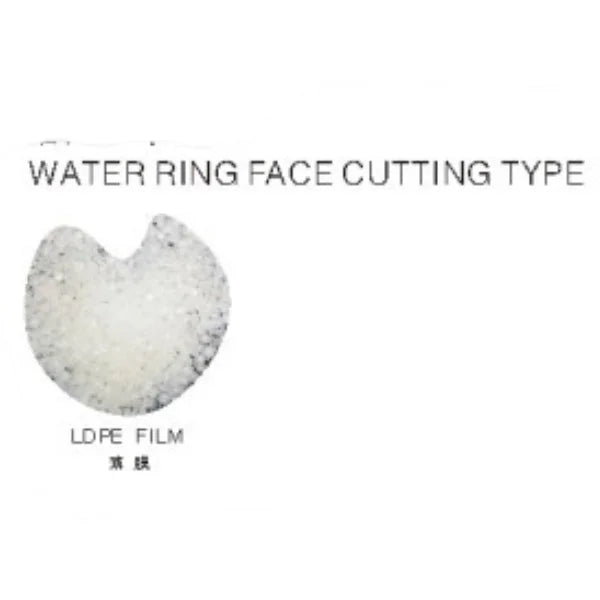

The No Heater Recycling Line uses a high-speed friction method instead of electric coils for heating during plastic granulation. This technology ensures eco-friendly plastic recycling without altering the physical properties of the material. It's ideal for HDPE, LDPE, PVC, and EVA compound film waste. The process conserves water, reduces emissions, and supports green manufacturing goals. With options for hot face cutting and water ring face cutting, users get flexible, high-efficiency output. The system supports a compact design, reduced energy usage, and plug-and-play operation. The granulator includes integrated screw extruders and high-output main motors. Custom hopper and cutter machine setups are available to meet different throughput needs.

Key Features

-

Heater-Free Friction Technology – No coil-based heating required during operation.

-

Supports Multiple Plastics – Ideal for HDPE, LDPE, EVA, and PVC waste films.

-

Two Cutting Options – Available in hot face or water ring cutting type.

-

Stable Granule Quality – Maintains plastic properties without degradation.

-

High Efficiency – Production rates from 60–250KG/H depending on model.

-

Green & Clean Operation – No waste gas or wastewater during granulation.

-

Power Savings – Reduces energy consumption by up to 40%.

-

Simple Maintenance – Easy to clean and operate with minimal setup.

-

Compact Layout – Optimized for small and mid-size facilities.

-

Main Motor Ranges – 37KW to 55KW power options available.

-

Flexible Screw Diameter – Choose between 110mm or 130mm extruder sizes.

-

Integrated Cutter Machine – Comes with belt and extruder-based cutter system.

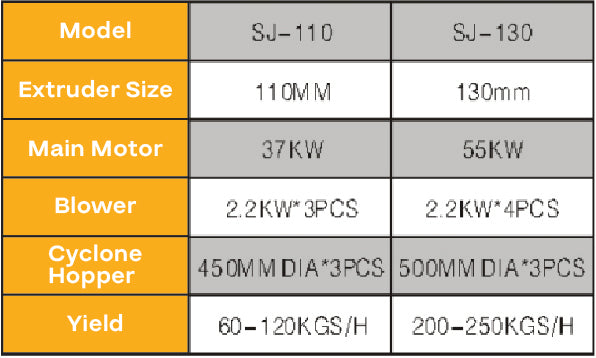

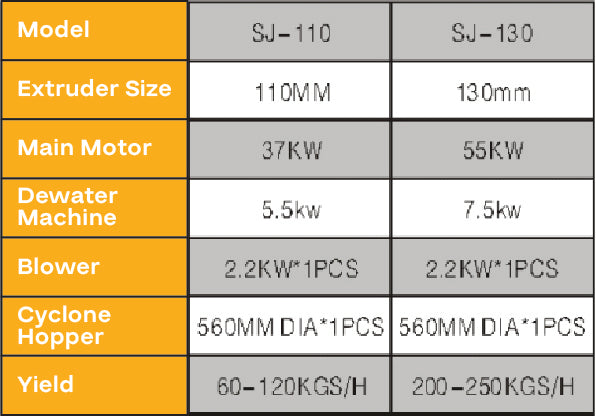

Product Models

| Model | Extruder Size | Main Motor | Dryer Motor | Cutter Machine Power | Die Plate | Yield |

|---|---|---|---|---|---|---|

| SJ-110 | 110mm | 37KW | 2.2KW × 3 PCS | 2.2KW × 1 PCS | Ø560mm × 1 PCS | 60–120 KG/H |

| SJ-130 | 130mm | 55KW | 2.2KW × 3 PCS | 2.2KW × 1 PCS | Ø560mm × 1 PCS | 200–250 KG/H |

The No Heater Recycling Line delivers efficient plastic granulation using friction-based heating, making it a clean, energy-saving solution. Compatible with HDPE, LDPE, PVC, and EVA, it's ideal for sustainable, high-output plastic recycling operations.

| Name | No Heater Plastic Recycling Line with Hot Face & Water Ring Cutting |

| Model | NO HEATER RECYCLING LINE |