Mould Temperature Controller with ±1°C Precision, Dual Heater System & Water/Oil Options

- SKU: MOULD TEMP.CONTROLLER

Actual Stock & Price Can Be Confirmed After Placing the Order.

The Mould Temp. Controller offers precise mold temperature regulation within ±1°C, increasing plastic part quality and reducing cycle times. Available in both water type and oil type, the unit supports direct and indirect cooling, depending on application. It features dual electric heaters, which can... See More

The Mould Temp. Controller offers precise mold temperature regulation within ±1°C, increasing plastic part quality and reducing cycle times. Available in both water type and oil type, the unit supports direct and indirect cooling, depending on application. It features dual electric heaters, which can operate independently or together, providing faster startup and higher energy savings (up to 35%). With Japanese, German, and Taiwanese components, it ensures long service life and operational reliability. Built-in buzzer alarms, circuit breakers, and pump protection systems enhance safety. Ideal for injection molding, extrusion, and die-casting, this controller provides consistent heat management for up to 200°C with both clean water and heat transfer oil.

Key Features

-

±1°C Control Accuracy – Maintains temperature stability during molding cycles.

-

Water and Oil Based Models – Choose between clean water or heat transfer oil.

-

Dual Heater System – Operate jointly or independently for faster heating.

-

Energy Savings Up to 35% – Efficient heater design minimizes electricity use.

-

Temperature Range Up to 200°C – Covers wide industrial heating needs.

-

Direct or Indirect Cooling – Adapts to molding and extrusion line configurations.

-

Built-in Safety Systems – Overheat, pump reverse, pressure, and dry-run protections.

-

Microcontroller-Based Control Panel – Digital interface for intuitive operation.

-

Auto Refill and Drain – Simplifies fluid management and maintenance.

-

Overload Alarm with BY-PASS Circuit – Ensures uninterrupted operation.

-

Compact and Portable – Designed for space-constrained workshops.

-

Widely Used Across Molding Applications – Injection, die-cast, blow molding setups.

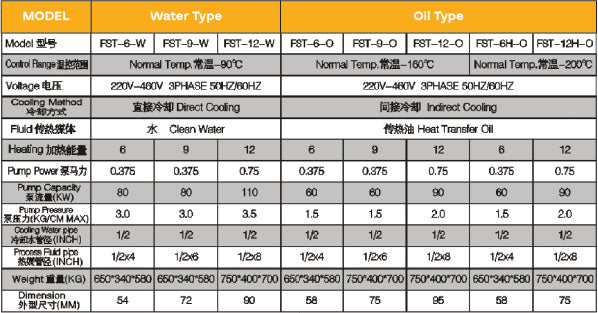

Product Models

| Model | Control Range (°C) | Voltage | Cooling Method | Fluid Type | Heating Power (kW) | Pump Power (kW) | Pump Capacity (L/min) | Pump Pressure (kg/cm²) | Inlet/Outlet Diameter (inch) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FST–6–W | Normal Temp. | 220V–460V 3PHASE 50/60HZ | Direct Cooling | Clean Water | 6 | 0.375 | 35 | 2.5 | 1/2 | 650×340×650 | 54 |

| FST–9–W | Normal Temp. | Same | Direct Cooling | Clean Water | 9 | 0.375 | 35 | 2.5 | 1/2 | 650×340×650 | 72 |

| FST–12–W | Normal Temp. | Same | Direct Cooling | Clean Water | 12 | 0.375 | 35 | 2.5 | 1/2 | 750×400×780 | 90 |

| FST–6–O | Normal Temp. ~160°C | Same | Indirect Cooling | Heat Transfer Oil | 6 | 0.375 | 35 | 2.5 | 1/2 | 650×340×650 | 58 |

| FST–9–O | Normal Temp. ~180°C | Same | Indirect Cooling | Heat Transfer Oil | 9 | 0.375 | 35 | 2.5 | 1/2 | 750×400×780 | 75 |

| FST–12–O | Normal Temp. ~200°C | Same | Indirect Cooling | Heat Transfer Oil | 12 | 0.375 | 35 | 2.5 | 1/2 | 750×400×780 | 95 |

| FST–6H–O | ~200°C | Same | Indirect Cooling | Heat Transfer Oil | 6 | 0.375 | 35 | 2.5 | 1/2 | 650×340×650 | 58 |

| FST–12H–O | ~200°C | Same | Indirect Cooling | Heat Transfer Oil | 12 | 0.375 | 35 | 2.5 | 1/2 | 750×400×780 | 75 |

The Mould Temp. Controller offers ±1°C precision, dual-heating operation, and oil/water compatibility for controlling mold temperatures up to 200°C. It ensures fast heat-up, energy savings, and safe operation across plastic and metal molding industries.

| Name | Mould Temperature Controller with ±1°C Precision, Dual Heater System & Water/Oil Options |

| Model | MOULD TEMP.CONTROLLER |