Heated Vertical Mixer with 2000KG Capacity, Dual-Layer Barrel & 15KW Heating System

- SKU: Heated Vertical Mixer

Actual Stock & Price Can Be Confirmed After Placing the Order.

The Big Vertical Mixer (With Heating) is designed for high-capacity plastic raw material mixing, including virgin, regrind, and color masterbatch materials. It features a helical spiral stirrer and built-in heating system for fast and uniform mixing. The stainless steel double-layer barrel enhances insulation, supporting... See More

The Big Vertical Mixer (With Heating) is designed for high-capacity plastic raw material mixing, including virgin, regrind, and color masterbatch materials. It features a helical spiral stirrer and built-in heating system for fast and uniform mixing. The stainless steel double-layer barrel enhances insulation, supporting thermal blending and moisture removal during processing. A 15KW heating pipe helps maintain a constant interior temperature, increasing drying efficiency and ensuring material consistency. With capacities ranging from 300KG to 2000KG, this mixer is ideal for industrial operations requiring precise control over mixing and heating. Its high-efficiency vertical design utilizes center dump-to-top circulation to reduce cycle time. Safe, easy to operate, and highly durable, it is suitable for injection molding, film production, and extrusion lines.

Key Features

-

Integrated Heating System (15KW) – Ensures heat-assisted material mixing and drying.

-

Double-Layer Stainless Barrel – Provides insulation and consistent thermal performance.

-

Helical Spiral Stirring – Fast and uniform mixing from bottom to top and back.

-

Available Capacities up to 2000KG – Meets small to large-scale production needs.

-

Compact Vertical Design – Maximizes space and mixing efficiency.

-

Easy-to-Clean Structure – Stainless finish prevents contamination and rust.

-

Supports Virgin + Masterbatch Mixes – Blends diverse materials evenly.

-

Electric Motor Options from 2.2KW to 5.5KW – High-torque operation with minimal power use.

-

Safety Features Included – Motor cutoff, screw protection, and access ladders.

-

Ideal for Heating & Dehumidification – Especially for moisture-sensitive polymers.

-

Compatible with Screw Loaders – Optional integration for feeding systems.

-

Short Mixing Cycles – Circulates material quickly for time-saving processing.

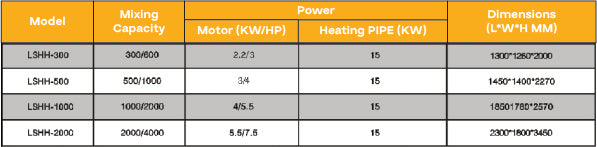

Product Models

| Model | Mixing Capacity (KG/L) | Motor Power (kW/HP) | Heating Pipe Power (kW) | Dimensions (L×W×H mm) |

|---|---|---|---|---|

| LSHH–300 | 300/600 | 2.2/3 | 15 | 1300×1280×2000 |

| LSHH–500 | 500/1000 | 3/4 | 15 | 1450×1400×2270 |

| LSHH–1000 | 1000/2000 | 4/5.5 | 15 | 1850×1780×2570 |

| LSHH–2000 | 2000/4000 | 5.5/7.5 | 15 | 2300×1800×3450 |

The Heated Vertical Mixer combines thermal drying and spiral mixing in one system, delivering fast, consistent blends of plastic materials with up to 2000 kg capacity. Ideal for industrial batch production, it’s built for performance, durability, and energy efficiency.

| Name | Heated Vertical Mixer with 2000KG Capacity, Dual-Layer Barrel & 15KW Heating System |

| Model | Heated Vertical Mixer |