Film Agglomerator for Thermoplastic Recycling with 1000L Volume & 700KG/H Output

- SKU: FILM AGGLOMERATOR

Actual Stock & Price Can Be Confirmed After Placing the Order.

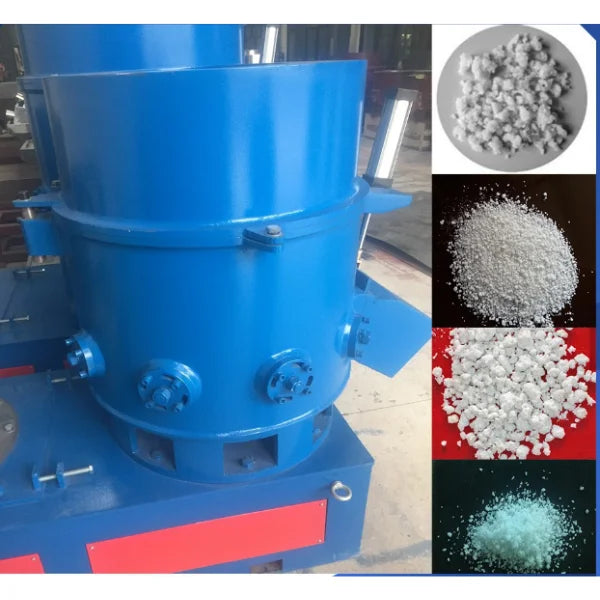

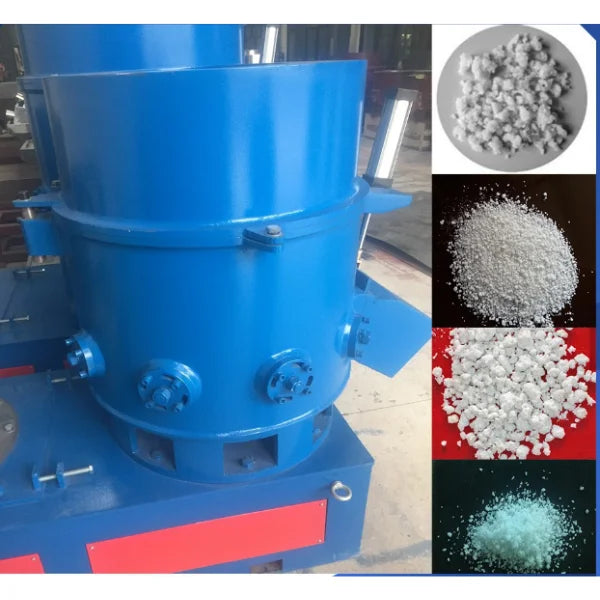

The Film Agglomerator is engineered to convert thermoplastic films and soft plastic waste (under 2mm thickness) into reusable granules for further processing. It is ideal for materials like PVC, HDPE, LDPE, PP, and PS. The high-speed rotary cutting mechanism, supported by 8 rotary and... See More

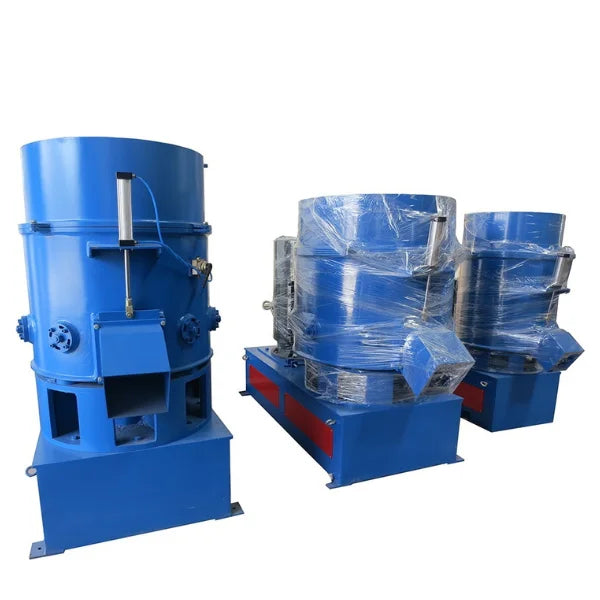

The Film Agglomerator is engineered to convert thermoplastic films and soft plastic waste (under 2mm thickness) into reusable granules for further processing. It is ideal for materials like PVC, HDPE, LDPE, PP, and PS. The high-speed rotary cutting mechanism, supported by 8 rotary and 8 fixed blades, ensures efficient shredding and melting action. With capacities ranging from 150KG/H to 700KG/H, the FAL series is available in multiple tank volumes up to 1000 liters. Each model operates at a stable rotating speed of 850 RPM, enabling uniform particle size and minimal thermal degradation. The compact layout, sturdy build, and high output performance make it ideal for plastic recycling plants, packaging factories, and thermoplastic processing units.

Key Features

-

Processes Thermoplastic Films <2mm – Efficient granulation of soft PVC, PE, PP, PS films.

-

Multiple Volume Options (200L–1000L) – Scale as per production requirements.

-

Up to 700KG/H Output – High-efficiency plastic conversion for industrial use.

-

8 Rotary + 8 Fixed Blades – Powerful and consistent shredding and blending performance.

-

Constant 850 RPM Speed – Maintains material uniformity and controlled heat distribution.

-

Integrated Heating by Friction – Eliminates the need for external heating systems.

-

Compact Design – Fits easily into recycling plants and small production lines.

-

Safe & Sealed Construction – Reduces dust, odor, and heat loss during processing.

-

Stainless Interior Coating – Durable and corrosion-resistant for longer life.

-

Granules Ready for Extrusion – Suitable for direct feeding into pelletizing machines.

-

Low Maintenance Operation – Simple blade access and easy cleaning.

-

Energy-Efficient Motors – Delivers maximum performance at optimized power input.

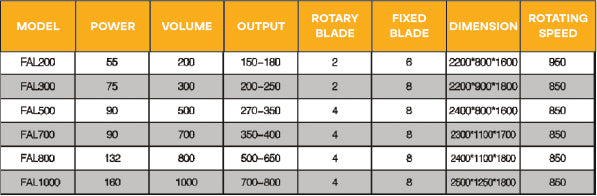

Product Models

| Model | Power (kW) | Volume (L) | Output (kg/h) | Rotary Blades (pcs) | Fixed Blades (pcs) | Dimensions (L×W×H mm) | Rotating Speed (RPM) |

|---|---|---|---|---|---|---|---|

| FAL200 | 55 | 200 | 150–180 | 2 | 6 | 2200×700×1800 | 950 |

| FAL300 | 75 | 300 | 200–250 | 2 | 6 | 2300×800×1800 | 850 |

| FAL500 | 90 | 500 | 300–400 | 4 | 8 | 2400×900×1800 | 850 |

| FAL700 | 110 | 700 | 500–600 | 4 | 8 | 2400×1000×1800 | 850 |

| FAL800 | 132 | 800 | 600–700 | 4 | 8 | 2400×1100×1800 | 850 |

| FAL1000 | 150 | 1000 | 700–800 | 4 | 8 | 2500×1250×1800 | 850 |

The Film Agglomerator converts thin plastic films into usable granules with up to 700KG/H output. With 850 RPM rotation, dual-blade systems, and capacities up to 1000L, it’s a reliable solution for soft plastic recycling.

| Name | Film Agglomerator for Thermoplastic Recycling with 1000L Volume & 700KG/H Output |

| Model | FILM AGGLOMERATOR |