Auto Vacuum Loader Series with Up to 350KG/H Conveying Capacity & Smart Motor Protection

- SKU: AUTO LOADER

Actual Stock & Price Can Be Confirmed After Placing the Order.

The Auto Vacuum Loader Series is designed for automatic, hands-free plastic material feeding from storage to processing machines. The 300G model features a compact stainless steel hopper, lightweight body, and carbon brush motor, perfect for small-volume applications. Meanwhile, the 700G, 800G, and 900G models... See More

The Auto Vacuum Loader Series is designed for automatic, hands-free plastic material feeding from storage to processing machines. The 300G model features a compact stainless steel hopper, lightweight body, and carbon brush motor, perfect for small-volume applications. Meanwhile, the 700G, 800G, and 900G models are equipped with induction motors, separated main frames, and high suction power ranging up to 1200mmHg, ensuring efficient conveying up to 350KG/H. All models include MCOM computerized controllers, automatic filter cleaning, and motor overload alarms. Easy to install, maintain, and operate, these loaders are ideal for injection molding, extrusion lines, and material recycling setups.

Key Features

-

Computerized Operation Program – Ensures fully automated and safe performance.

-

Separated Main Frame & Hopper (700G–900G) – Enhances convenience and safety.

-

High-Speed Suction (Up to 1200mmHg) – Quickly transfers materials over long distances.

-

Carbon Brush or Induction Motor Options – Tailored for different operational needs.

-

Overload Protection System – Smart alarm prevents motor and equipment damage.

-

Stainless Steel Hopper (All Models) – Durable, rustproof, and hygienic.

-

Low Maintenance Design – Quick filter access and replaceable motor components.

-

Compact Build for Easy Placement – Fits seamlessly beside any processing equipment.

-

Reservoir Volume 7.5L – 12L – Suitable for both low and high-volume material transfer.

-

Voltage Options from 220V to 380V – Compatible with multiple regional setups.

-

Conveying Capacity up to 350KG/H – Ideal for continuous operation.

-

Optional Electricity Eye for Sensing – Enables real-time level detection and feeding control.

Product Models

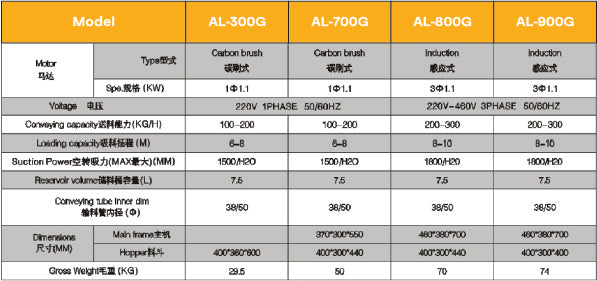

| Model | Motor Type | Motor Spec. (kW) | Voltage | Conveying Capacity (kg/h) | Loading Capacity (kg) | Suction Power Distance (mm) | Reservoir Volume (L) | Conveying Pipe Inner Dia. (mm) | Main Frame Size (mm) | Hopper Size (mm) | Gross Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AL–300G | Carbon brush | 1Φ1.1 | 220V 1PHASE 50/60HZ | 100–200 | 5–8 | 1800 | 7.5 | 38/50 | 370×300×530 | 400×360×600 | 23.5 |

| AL–700G | Carbon brush | 1Φ1.1 | 220V 1PHASE 50/60HZ | 100–200 | 5–8 | 1800 | 7.5 | 38/50 | 370×300×530 | 400×360×600 | 25 |

| AL–800G | Induction | 3Φ1.1 | 380V 3PHASE 50/60HZ | 200–300 | 5–8 | 4000 | 7.5 | 38/50 | 470×370×620 | 400×360×600 | 35 |

| AL–900G | Induction | 3Φ1.1 | 380V 3PHASE 50/60HZ | 300–400 | 15 | 4000 | 7.5 | 38/50 | 470×370×620 | 400×360×600 | 38 |

The Auto Loader Series supports automated material feeding with up to 350KG/H output, offering carbon or induction motor variants with smart overload alarms and stainless steel hoppers. Built for flexibility and reliability, it fits all plastic processing lines.

| Name | Auto Vacuum Loader Series with Up to 350KG/H Conveying Capacity & Smart Motor Protection |

| Model | AUTO LOADER |